Sidewall coring

| Development Geology Reference Manual | |

| |

| Series | Methods in Exploration |

|---|---|

| Part | Wellsite methods |

| Chapter | Sidewall coring |

| Author | Lee Whitebay |

| Link | Web page |

| Store | AAPG Store |

Sidewall coring systems have been developed to obtain core samples after a well has been drilled and logged. The tools can be precisely positioned in zones of interest using gamma logs or SP logs as guides. Percussion or rotary drilled samples provide small bits of formation material, suitable for geological and engineering studies. Other systems such as the new Sidetrak Coring System® cut a more conventional type of core angled off to the side of the hole. Sidewall cores are an excellent cost effective way to increase knowledge of formations. However, sidewall cores should not be used in lieu of whole cores since the discontinuous sampling could lead to misinterpretation of the geological sequence.

Percussion sidewall coring

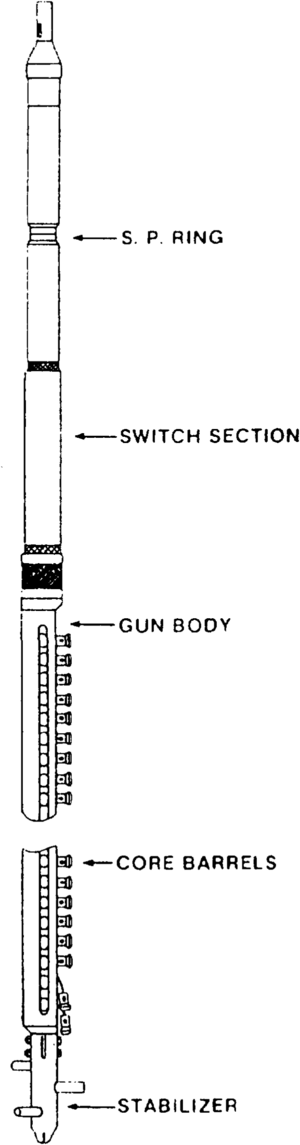

Most sidewall cores are obtained by percussion sidewall coring systems (Figure 1). These tools shoot hollow, retrievable, cylindrical bullets 1 in. wide by 1.75 in. long into the borehole wall. The tool (gun) can be combined in multiples of approximately 30 bullets with 120 shots a general maximum. The gun is lowered to the desired depth, then individual bullets are electrically fired from the surface. The bullets remain connected to the gun by wires, and movement of the gun pulls the bullets from the borehole wall.

Different bullet “core barrel” designs are available for unconsolidated, soft, and medium to hard formations. Therefore, it is wise to have more than one type of core barrel on location until acceptable core recovery can be demonstrated. Figure 1 illustrates a typical percussion sidewall coring tool.

The advantages of this coring system are speed, low cost, and the precise ability to sample zones of interest after open hole logs have been run. The disadvantage is that the bullet usually alters the formation by shattering harder rock or compressing softer sediments, thereby reducing the quantitative value of the sidewall core analysis data. Also, percussion sidewall core recovery tends to be low in very hard or fractured rock.

Rotary sidewall coring

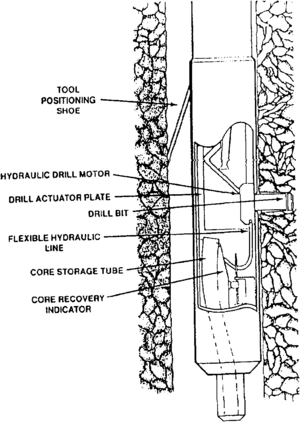

The rotary, or drilled sidewall coring tool, was developed to recover sidewall core samples without the shattering impact of the percussion system. Suitable for hard to friable rock, the rotary sidewall corer uses a diamond-tipped drill to cut individual plugs from the sidewall. The samples are broken off and pulled from the sidewall by the core drill. The drill is then retracted into the body of the tool where the samples are deposited. The tool is moved to a new sample location after depositing each sample. A “gun” of 30 samples, each 0.9375 in. wide by 1.75 in. long, can be taken during one trip.

The advantage of the rotary sidewall coring system is that it produces samples suitable for quantitative core analysis. The disadvantages are high cost per sample and longer time per recovered core. Rotary sidewall core recovery is low in unconsolidated formations. Figure 2 shows how a rotary sidewall coring tool operates.

Sidetrak coring system

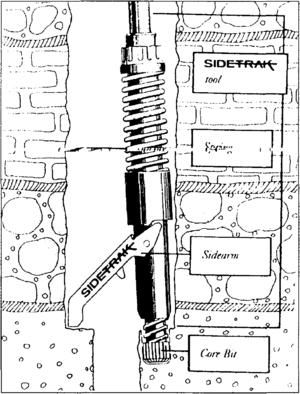

A new Sidetrak Coring System® is just coming on the market and merits discussion for two reasons. First, the system is designed to acquire a larger, more continuous core sample from a drilled and logged wellbore than is possible with existing sidewall coring tools. Second, the emergence of a new tool confirms there is still room for improvement in the area of acquiring high quality, low cost core samples.

A very close cousin to a conventional core barrel, the Sidetrak Coring System is designed to cut up to length::10 ft of 2.5-in. core. The tool is attached to a conventional drill string and is lowered into the zone of interest. An integral arm pushes the core barrel against one side of the wellbore, resulting in a slightly sidetracked core. This tool is still in the development stage, but it shows promise and should be available in the future. Figure 3 shows a prototype of the new Sidetrak Coring System.

Wellsite handling of sidewall cores

Sidewall core handling procedures are always influenced by the objectives of the coring program, but a few items are constant for every job. First, unconsolidated samples must be stabilized prior to shipping. Second, time is of the essence, especially when saturations are to be determined. Finally, there can never be too much information on a sample container or data sheet.

Stabilization

Unconsolidated samples, especially those designated for detailed petrographic or petrophysical studies, must be stabilized to prevent deterioration during shipping. Stabilization can take the form of freezing, jacketing the samples with aluminum foil or lead sleeves, or leaving the samples in the bullets. Freezing samples is usually a good method for stabilizing clean oil or gas sands, but is a less attractive choice as the clay and water content increases.

Time factor

The time factor is important when evaluating all formations. The time between extraction of the sample from the bullet and packaging should be minimized to prevent the cores from drying out. The faster a sample is examined, wrapped, and sealed either in a glass jar or a ProtecCore® sleeve, the more accurate the fluid saturation analysis will be. Dictating the core descriptions into a portable tape recorder can speed up this work and make more complete descriptions.

Procedure

A typical sidewall core handling operation begins by examining the gun to determine if all the bullets had fired. Next, the cores are extracted from the bullets, described, and wrapped in plastic wrap and aluminum foil. The wrapped cores should be sealed in glass jars or ProtecCore sleeves as soon as possible. The sample containers should be labeled with the sample depth, operator's name, and well name. The detailed sample description should be on a separate sheet that accompanies the samples.

See also

- Mudlogging: drill cuttings analysis

- Introduction to wellsite methods

- Conventional coring

- Core handling

- Core alteration and preservation

- Show evaluation

- Core orientation