Cased hole tools

| Development Geology Reference Manual | |

| |

| Series | Methods in Exploration |

|---|---|

| Part | Wireline methods |

| Chapter | Basic cased hole tools |

| Author | Mark W. Alberty |

| Link | Web page |

| Store | AAPG Store |

Purpose of measurements

Basic formation evaluation measurements are made through casing for three general reasons:

- To supplement measurements taken in open hole. It may be necessary to supplement open hole measurements because the well conditions may preclude the possibility of reliably or safely making the necessary open measurements or because insufficient or inappropriate open hole measurements were taken over particular zones.

- To monitor the changes in formation properties that have occurred since the casing was set. During the life of a well, changes in saturation of the pore space by oil, gas, and/or water may be induced by sustained production. When these changes occur, evaluation of the nature of the changes may be necessary to design more effective hydrocarbon recovery strategies.

- To provide a depth reference between open hole and cased hole measurements and services.

Basic tools

The basic cased hole tools can be divided into three general groups: correlation, saturation, and porosity. The correlation device is used to correlate cased hole measurements with open hole measurements and to estimate shale volume. The saturation device is used to determine water saturation when porosity and water salinity are known. The porosity devices are used to estimate porosity when lithology is known. Table 1 lists the types of devices used for these purposes, and Table 2 gives the resolutions and limitations of the various devices. (For more details on tool specifications, see Basic tool table.)

| Application | Type of Device |

|---|---|

| Correlation | Gamma ray |

| Spectral gamma ray | |

| Saturation | Pulsed neutron |

| Porosity | Compensated neutron |

| Pulsed neutron |

| Tool | Vertical Resolution | Radius of Investigation | Applications | Limitations |

|---|---|---|---|---|

| Gamma ray | length::2 ft | length::12 in | Well-to-well correlation and estimates Vsh | Affected by radioactive scale near perforations |

| Spectral gamma ray | length::3 ft | length::16 in | Well-to-well correlation and estimates Vsh | — |

| Pulsed neutron | length::2 ft | length::18 in | Determines water saturation and estimates porosity | Does not work in freshwater and severely underestimates porosity in the presence of gas |

| Compensated neutron | length::3 ft | length::10 in | Estimates porosity | Severely underestimates porosity in the presence of gas |

Gamma ray tool

The gamma ray measurement responds to naturally occurring gamma rays from the formation. These gamma rays are able to penetrate steel casing. This permits the gamma ray to be used in a cased hole for correlation with open hole logs, for the discrimination of sands and shales, and for the calculation of shale volume. Its use is essentially identical to its use in an open hole with the exception of minor environmental corrections needed for the influence of the steel casing and cement. A common problem encountered in the cased hole use of the gamma ray device is scaling of radioactive salts in casing. When produced water containing dissolved radioactive salts enters the casing, the encountered drop in pressure may cause the salts to precipitate from the waters and deposit on the casing near the perforations. These salts will normally dominate the gamma ray response near the perforations, making the gamma ray useless in those intervals for both correlation to open hole or the estimation of shale volume. If the salts are predominantly uranium, their influence can be removed through the use of the spectral gamma ray. However, if the salts are in part potassium, their influence cannot normally be corrected through the use of the spectral gamma ray. The gamma ray is usually run in combination with a collar locator to provide a depth reference for mechanical cased hole services. (For information on the open hole gamma ray tool, see Basic open hole tools.)

Compensated neutron tool

The compensated neutron measurement is little affected by the presence of steel casing. This permits the compensated neutron to be used in cased hole to estimate porosity when lithology is known. However, the presence of gas in the formation will cause the compensated neutron to underestimate porosity significantly. (For more information on the compensated neutron tool, see Basic open hole tools.)

Pulsed neutron tool

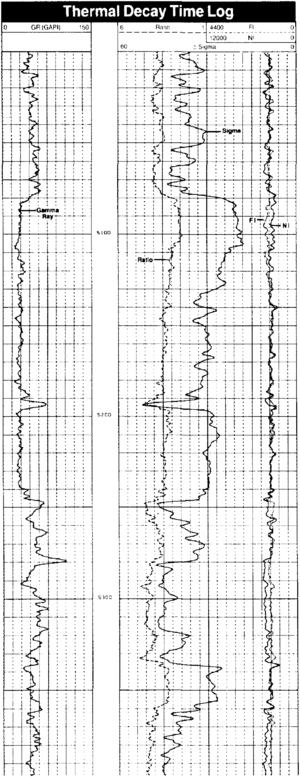

Pulsed neutron devices are electronic devices that generate pulses of high energy neutrons. These high energy neutrons bombard the formation, losing energy as they collide with atoms of the rock. Eventually, the neutrons lose so much energy that they are captured (generally by chlorine that exists as part of the salt dissolved in the formation waters). When a neutron is captured, a gamma ray is emitted. The detectors in the pulsed neutron tool are designed to measure these “capture” gamma rays, thus, a “capture cross section” of the formation through casing can be determined. This formation property allows one to estimate the water saturation when porosity and formation water salinity are known. A typical pulsed neutron log is shown in Figure 1.

The gamma rays detected by the pulsed neutron devices can also be processed in a manner similar to the compensated neutron and provide a very similar estimation of porosity. This estimation of porosity can be reasonably good when the formation water is relatively salty and the formation does not contain significant amounts of gas. This combined measurement of capture cross section and porosity from this single device allows the pulsed neutron to be used frequently as a single pass cased hole formation evaluation device. As with the compensated neutron, the presence of gas in the formation will cause the pulsed neutron to underestimate porosity significantly.

The production of fluids from a reservoir causes changes in the water saturations of producing reservoirs. Cased hole measurements of the changes in formation saturations are an extremely important diagnostic tool for the development of strategies for complete hydrocarbon recovery. Bypassed zones can be identified by their virgin state saturations. Intervals of water breakthrough can be identified by their high water saturations. Candidate zones for secondary and tertiary recovery techniques can be identified through evaluation of residual hydrocarbon saturation measured in cased hole by pulsed neutron devices.

Techniques to determine the residual oil saturation of reservoirs are most accurate when contrasting fluids can be injected into the formations to displace natural formation waters. This method of logging the formation with native waters, then injecting contrasting waters and logging again, has become known as log-inject-log techniques. These techniques are most easily accomplished when casing is in place to provide a means to inject the fluids. This method provides the pulsed neutron with an advantage over open hole logging methods in accurately determining the amount of oil available for secondary or tertiary recover methods.

New developments

As the interest in and need for greater formation evaluation capabilities grow, the industry continues to develop newer and more sophisticated measurements in through-casing applications. Pulsed neutron spectroscopy is a promising method to measure lithology, porosity, and saturations through casing, even in the presence of freshwater. These devices are being developed and have had limited commercial exposure. Their basic principle lies in activating elements through bombardment by very high energy neutrons. The energy of the activated gamma rays are measured and used to perform elemental analysis of the matrix and/or the fluids. Variations are being marketed under the general names of carbon/oxygen logs or gamma spectroscopy, Other companies are testing resistivity devices that measure formation resistivity through casing. The advent of full waveform acoustics have enabled some vendors to successfully measure the velocity of compressional and/or shear waves in formations behind casing, under appropriate conditions.

See also

- Difficult lithologies

- Dipmeters

- Formation evaluation of naturally fractured reservoirs

- Basic open hole tools

- Basic tool table

- Introduction to wireline methods

- Determination of water resistivity

- Preprocessing of logging data

- Wireline formation testers

- Standard interpretation

- Quick-look lithology from logs

- Borehole imaging devices

References

- ↑ Schlumberger Well Services, 1986, Schlumberger Production Services Catalog: Houston, TX.