Pressure detection

| Development Geology Reference Manual | |

| |

| Series | Methods in Exploration |

|---|---|

| Part | Wellsite methods |

| Chapter | Pressure detection |

| Author | Parke A. Dickey |

| Link | Web page |

| Store | AAPG Store |

Normal reservoir pressure is the pressure in the reservoir fluids necessary to sustain a column of water to the surface.[1] Normal pressures range between 0.43 and 0.50 psi/ft. Normal drilling muds weigh about 9 ppg (pounds per gallon) and exert a bottom hole pressure of approximately 0.47 psi/ft of depth.

By convention in the petroleum industry, overpressure refers to pressures higher than normal that require heavy drilling mud to keep formation fluids from entering the borehole. Pressures lower than normal are called subnormal.

Overpressured reservoirs

Drilling problems with overpressured reservoirs

Notable effects of overpressured reservoirs that are costly include the following:

- Blowouts—uncontrolled production of formation fluids

- Caving—high pore pressure in low permeability rocks causes them to stress relieve or “cave” into the borehole

- Stuck pipe—the drill pipe adheres to the side of the borehole due to the swelling (stress relief) of the borehole walls behind the bit

- Lost circulation—by raising the mud weight to control the formation pressure at the bit, the formation may rupture. The mud will then run out into a cavity of its own making.

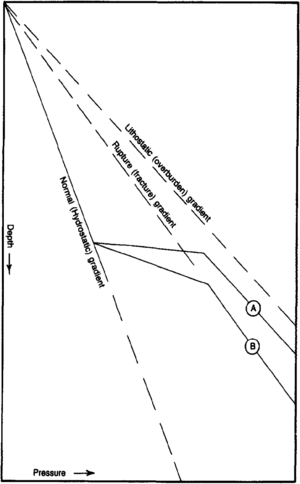

When drilling in areas where overpressured zones are known to occur, it is necessary to be aware of both the pressure of the fluids in the pores and the pressure at which the formations will fracture. It is not enough simply to drill with heavier mud to prevent blowouts. If the mud is too heavy, the formation will rupture and lost circulation will result. It is usually impossible to determine these critical pressures in a new area in advance of drilling.

Geological cause of overpressured reservoirs

There is considerable debate and literature on the causes of overpressure. This section outlines some common explanations.

Arrested compaction of shale

The most commonly accepted cause of overpressure is arrested compaction of shale. Compaction requires the expulsion of pore water. When clays first start to compact, they are quite permeable and most of the water moves upward. As compaction continues, however, the clay flakes become parallel, reducing vertical permeability. Sands and silts compact less than clays and shales and can maintain permeability to greater depths.

As long as there is a silty or sandy bed within a few feet of the shales, the shales continue on a normal compaction trend. However, if no sandy beds are present, the water remains in the shale pores. As additional overburden is deposited, the shale then has to sustain all or part of the additional weight. This results in high pressure in the shale pore water. If there is a small, isolated sand body enclosed by the shale, whatever fluid it contains (water, oil, or gas), will share the same pressure. The fact that overpressures have been maintained for hundreds of millions of years over small vertical intervals indicates that the permeability of the enclosing shales can be virtually zero.

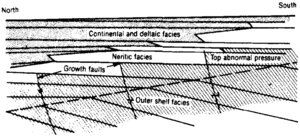

The distribution of reservoirs and overpressuring is strongly controlled by the depositional environment (Figure 1). Overpressured reservoirs are commonly found where there are thick deposits of shaly sediments.

Aquathermal effects

Aquathermal effects also cause overpressure. The temperature increases as sediment is buried, causing an increase in the volume of water. This in turn results in an increase in pressure if the sediment is sealed by an impermeable layer.[4]. For example, if a shale is totally sealed and there is no dilation to increase the pore volume, and if the geothermal gradient is temperature::25°C per depth::1000 m, then the pressure increase is about 1.8 psi per ft. This is more than the increase in weight of the overburden. Consequently, this aquathermal pressuring will cause an increase of pressure up to the pressure at which the rocks fracture (Figure 2).

Pressure data from some U.S. Gulf coast wells suggest that the aquathermal effect is important.

Tectonic phenomena

Tectonic phenomena also produce overpressures. In the Gulf of Alaska, fluid pore pressures up to 0.85 psi per ft were found due to horizontal compressive stress in the rocks. In Western Alberta, large thicknesses of Paleozoic carbonates have been thrust over soft Cretaceous shales, resulting in overpressuring of the lenticular oil-bearing sandstones that extend under the overthrust (such as Leafland and Pembina).

Thermal cracking of organic matter

The thermal cracking of organic matter may cause an increase in the volume of fluids, which would in turn cause an increase in pressure.

Other causes

Other suggested causes of overpressuring include the loss of water in smectite clay as it changes to illite, osmotic pressures due to salinity variations in the water, and effects of cementation.

Prediction of overpressure before drilling: seismic detection

As shales compact, the velocity of seismic waves increases so that seismic wave velocity normally increases with depth. If the shales have not been able to compact, the seismic velocity will be less.

Interval velocity can be determined from the surface by the common depth point method of seismic acquisition. If interval velocity increases normally with depth and then decreases, it is possible that a zone of overpressure exists. This method of predicting the depth to an overpressured zone has been widely used, especially in the offshore Gulf coast of the United States.

Detection of overpressure while drilling

Drilling rate

When drilling shales, the drilling rate normally decreases with depth as the shales become more compact. If the drilling rate increases, it can be inferred that an overpressured zone is being encountered. The rate increases because bottom hole conditions change from overbalanced to underbalanced.

Because lithology, rotary speed, and weight on the bit also affect drilling rate, a corrected drilling rate called “d exponent” should be used (Equation 1). This method can be one of the most reliable indicators that the drill is penetrating a zone of abnormally high pressure.

where

- R = rate of penetration in feet per hour,

- N = rotary speed in revolutions per minute,

- W= weight on bit in pounds, and

- D = hole diameter in inches[5].

Mud tank level

A rising level of mud in the tanks indicates that more mud is coming out of the hole than is going in. This is called a “kick.” This happens because formation fluids are entering the hole and the well is threatening to blow out. The situation is extremely serious, and proper steps must be taken to get the gas, oil, or water out of the hole. The most common method is to close the blowout preventers and stop the pumps. After a few minutes, the pressure at the top of the drill pipe will equal the pressure in the formation minus the weight of the column of mud. This is the excess pressure that must be balanced by increasing the mud weight. The pumps are then started to circulate the extraneous fluid out of the hole. The drill pipe pressure is carefully controlled with the choke. If the equilibrium drill pipe pressure is exceeded, the well may lose circulation, and if it is too low, the well will blow out.

Delayed indications

Several other indications of overpressure may occur after the lag time necessary for the mud to return to the surface from the bottom of the hole. They are much less reliable than the drilling rate, but can be monitored by mudlogging equipment. These indicators include the following:

- Drilling mud gas—Gas in the drilling mud often increases because methane is dissolved in the pore water of some overpressured shales. As the cuttings and cavings come up the hole, the gas escapes and can be detected in the mud. Gas in the mud is also caused by oil- or gas-bearing formations and by organic-rich shales.

- Shale density—Undercompacted shales, characteristic of overpressured zones, have a lower density (because of abnormally high porosity) than normal shales at a given depth. The density of shale cuttings can be measured by several methods. Also, the shape of drill cuttings from undercompacted shales may be different than those from normally compacted shales.

- Temperature—There may be an increase in the temperature of the mud returns. Although it has been widely claimed that the geothermal gradient is higher in overpressured shales because of their abnormally high porosity and lower thermal conductivity, a doubling of shale porosity from 10 to 20% should cause a decrease in conductivity of only about 1% (with a correspondingly small increase in geothermal gradient). Thus, the increase in temperature is probably due to faster drilling and increased cavings in undercompacted shales.

Detection of overpressure with well logs

Figure 3 Electric logs of two wells offshore Louisiana. Well A had normal pressure. Well B, 2000 ft away and across a growth fault, showed a sudden decrease in resistivity of shale (increase in conductivity) at about 11,100 ft. Shortly thereafter, the well showed indications of an impending blowout.[6]

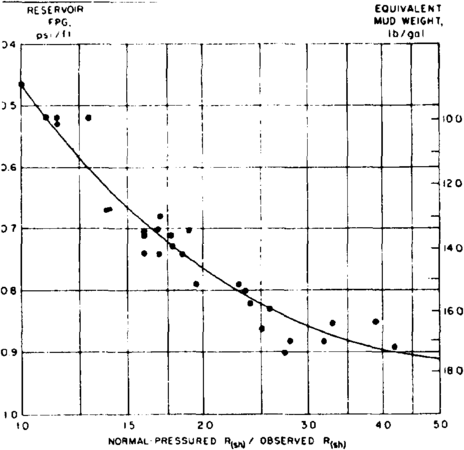

Figure 4 Shale resistivity parameter, resistivity of normally pressured shale divided by observed resistivity of abnormally pressured shale, plotted against formation pressure gradient (FPG) and equivalent mud weight.[7]; by permission of SPE

Undercompacted shales associated with overpressured zones have a much lower electrical resistivity than normally compacted shales (Figure 3). According to the Archie formula, doubling the porosity of a shale from 10 to 20% should cause its resistivity to drop to one-fourth. As a result, it is possible to determine accurately the degree of undercompaction of a shale from its resistivity and to estimate the pore pressure (Figure 4).[7]

Because undercompacted shale has slow seismic velocity and low density, a high pressure zone can also be identified from sonic and density logs.[8]

Note that as is always the case with well logs, there are pitfalls in interpretation, and the local geology and hole conditions must be taken into account.

Subnormally pressured reservoirs

Subnormal reservoir pressures, that is, pressures less than 0.43 psi per ft of depth, are very common.[9] The cause of abnormally low reservoir pressures is not well understood. If a reservoir containing either gas or oil is isolated and then subjected to uplift and erosion, the removal of overburden causes an elastic rebound of the solids and an increase in volume of the pores. The elastic dilation of sandstones is about 7 × 10–6 volumes per psi. Water expands only 3 × 10–6 volumes per psi, so that the pressure of the pore water in the aquifer and the enclosing shales will drop, possibly sucking some of the water out of the aquifer. Most low pressure reservoirs are in areas where there has been uplift and erosion since the sediments forming the reservoir were deposited and lithified.

Drilling problems with subnormally pressured reservoirs

Much less attention has been paid to subnormally pressured reservoirs than to overpressured reservoirs. This is probably because there are fewer spectacular drilling problems associated with subnormal pressures and underpressures. However, problems exist that can be serious.

If the reservoir pressure is much lower than the pressure in the drilling fluid, severe formation damage can occur. The drilling mud filtrate penetrates the reservoir, causing swelling and migration of clays, which may plug the pore throats. Even a little water in the hole can kill a low pressure producing gas well. The water is drawn into the pores by capillarity and ruins the relative permeability to gas. In the case of low pressure gas sandstone reservoirs, it is desirable to set casing at the top of the reservoir interval and drill with gas, salt water, or oil-based mud to minimize formation damage.

Also, if the gas reservoir has a low pressure, there may be no indication of gas on the mudlog. The logs of many abandoned dry holes should be reexamined to look for bypassed gas zones.

See also

- Drilling problems

- Introduction to wellsite methods

- Drilling fluid

- Wellsite math

- Wellsite safety

- Rate of penetration

- Well planning

- Measurement while drilling

References

- ↑ Fertl, W. H., 1976, Abnormal formation pressures: New York, Elsevier Scientific Publishing Company, 382 p.

- ↑ Dickey, P. A., C. R. Shriram, and W. R. Paine, 1968, Abnormal pressures in deep wells of southwestern Louisiana: Science, May 10, v. 160, p. 609–615., 10., 1126/science., 160., 3828., 609

- ↑ Barker, C., and B. Horsfeld, 1982, Mechanical versus thermal cause of abnormally high pore pressures in shales— discussion: AAPG Bulletin, v. 66, n. 1, p. 99–100.

- ↑ Barker, C., 1972, Aquathermal pressuring—role of temperature in development of abnormal pressure zones: AAPG Bulletin, v. 56, n. 10, p. 2068–2071.

- ↑ Jorden, J. R., Shirley, O. J., 1966, Application of drilling performance to overpressure detection: Journal of Petroleum Technology, v. 18, p. 1387–1394., 10., 2118/1407-PA

- ↑ Wallace, W. E., 1965, Abnormal subsurface pressures measured from conductivity or resistivity logs: The Log Analyst, v. 6, p. 26-38.

- ↑ 7.0 7.1 Hottman, C. E., Johnson, R. K., 1965, Estimation of formation pressures from log-derived shale properties: Journal of Petroleum Technology, v. 17, p. 717–723., 10., 2118/1110-PA

- ↑ Magara, K., 1978, Compaction and fluid migration: New York, Elsevier Scientific Publishing Company, 319 p.

- ↑ Dickey, P. A., Cox, W. C., 1977, Oil and gas reservoirs with subnormal pressures: AAPG Bulletin, v. 61, n. 12, p. 2134–2142.