Types of completions

| Development Geology Reference Manual | |

| |

| Series | Methods in Exploration |

|---|---|

| Part | Production Engineering Methods |

| Chapter | Well Completions |

| Author | Stephen A. Holditch |

| Link | Web page |

| Store | AAPG Store |

Completions can be divided into three categories: open hole completions, liner completions, and perforated casing completions. In most wells, conventional single perforated casing completions are used; however, multiple, alternate, or slim hole completions may be used under certain conditions. The choice of completion type should be closely coordinated with the development of the reservoir management plan. For example, the size, weight, and grade of the tubular goods will be determined based upon the ultimate use of a wellbore. An injection well may require stronger casing than a production well.

Open hole completions

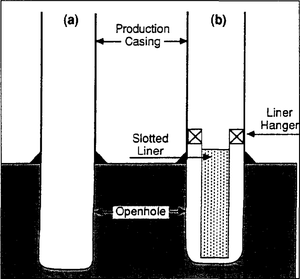

Open hole completions were originally used in the early days of the petroleum industry when most wells were drilled with cable tools. Normally, casing was run as the hole was drilled. When the formation was penetrated and oil and gas began to flow, drilling ceased and the well was produced as an open hole completion. As rotary rigs began to drill a majority of the wells, it was still common to complete a well using an open hole completion. If the well needed to be stimulated, nitroglycerine was used to rubbleize the formation near the wellbore. Figure 1(a) illustrates a typical wellbore diagram for an open hole completion. Although not common in most areas, open hole completions are still used today in certain situations, such as the horizontal well completions in the Austin Chalk and in the Devonian shales in Appalachia. In a typical open hole completion, casing is set prior to drilling into the producing interval. A nondamaging fluid can then be used to drill into the pay section.

One important disadvantage of an openhole completion is that production casing must be set prior to drilling and logging the reservoir. If for some geological or engineering reason the target formation is not productive, then money has been spent to set casing in a well that may be plugged as a dry hole. Another disadvantage is the lack of control that occurs when an open hole completion is made. One cannot control the flow of fluids from the reservoir into the wellbore nor the injection profile in an open hole completion. In addition, if the formation is not competent, sloughing zones can cave into the wellbore and restrict flow to the surface.

Liner completions

Liner completions are similar to open hole completions in that casing must be set prior to drilling the producing interval. The advantage of a liner completion is that the drilling fluid system can be changed and a nondamaging fluid used to drill the pay interval. Several types of liner completions are commonly employed in well completions. These include

- Slotted liner

- Screen and liner

- Cemented liner

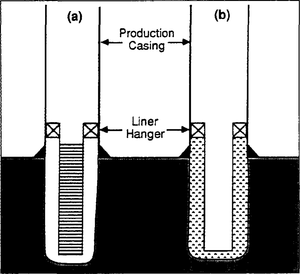

The slotted liner completion is similar to an open hole completion and has all the major advantages and disadvantages discussed for open hole completions. The only difference is that a slotted liner is hung in the open hole interval to minimize sloughing of the formation into the well bore (Figure 1b). A screen and liner completion is similar to the slotted liner completion in that a screen and liner is set in the open hole section of the wellbore. The difference is that gravel is sometimes placed behind the screen (Figure 2a). The advantages and disadvantages are the same as for open hole completions. The screen and liner completion is used primarily in unconsolidated formations to prevent the movement of formation materials into the wellbore, restricting the flow of reservoir fluids.

The cemented liner completion is used when intermediate casing is set in a well prior to reaching total depth (Figure 2b). Many times intermediate casing is used to isolate zones behind pipe such as low pressured intervals that tend to cause lost circulation problems or to isolate zones such as sloughing shales or salt layers. Intermediate casing is also set in transition zones between normally pressured intervals and geopressured intervals. After the casing is set, the weight or chemistry of the drilling fluid can be changed to continue drilling the well. The cemented liner completion is advantageous because the particular intervals behind the liner can be selectively perforated. This selection will allow one to control both the production and injection of fluids in those intervals. he main disadvantage of a cemented liner is the difficulty encountered in obtaining a good primary cement job across the liner. If a good cement job is obtained, then a cemented liner completion is very similar to a perforated casing completion.

Perforated casing completions

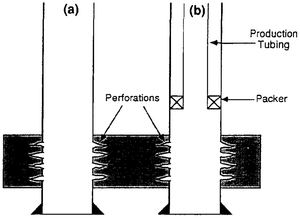

A perforated casing completion, illustrated in Figure 3a, is the most commonly used completion technique today. The main advantage of this type of completion is that the well can be drilled and logged to total depth prior to running and cementing production casing. By obtaining cores and logs of the potential producing interval, one can estimate the economic value of that wellbore prior to committing funds to complete the well. Another advantage of a perforated casing completion is that it is easier to obtain a good cement job, compared to a liner completion. If the primary cementing job is properly performed, one can selectively produce from and inject into the reservoir and isolate intervals as required. The production of an unconsolidated formation can be accomplished by performing an inside gravel pack. Finally, the perforated casing completion is quite adaptable to multiple completions and alternate completions.

Single completions

Once the decision has been made to either complete a well using an open hole completion, liner completion or perforated casing completion, a decision must be made on how many different intervals will be produced. The most common method is the single completion in which only one interval is produced at a time (Figure 3b). A single completion is simple and results in fewer operating problems and less cost than multiple completions. Single completions are common on land where the reservoirs are either shallow or very deep. If the formation is very shallow, then drilling costs are minimal and single completions are usually best. In very deep wells, single completions are preferred because of the complexity and expense involved with a dual or triple completion in reservoirs deeper than depth::10000 ft.

Multiple completions

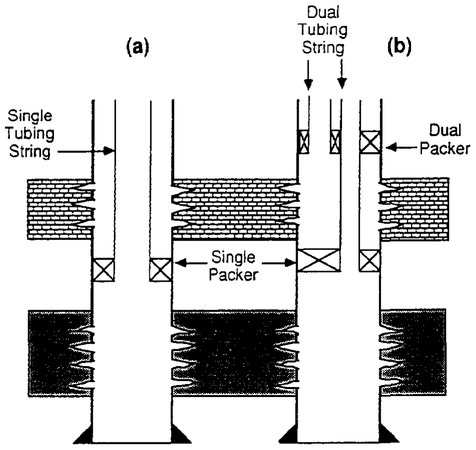

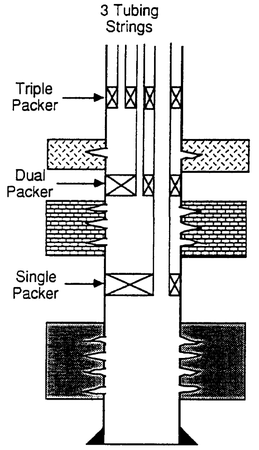

In certain cases, multiple completions may provide the best control of reservoir operations. Multiple completions include the tubing-casing dual, dual tubing strings, and the typical triple completion consisting of three tubing strings. Figures 4 and 5 illustrate these multiple completions.

The more complex the completion, the more trouble one can expect in both completion operations and in subsequent workover operations. Multiple completions should be considered only in special situations. These situations include areas where drilling costs are very high or where the area allocated for drilling wells is at a premium. Such areas include offshore areas, highly populated areas, and remote land locations.

The main advantage of multiple completions is that two or more reservoirs can be simultaneously produced from a single wellbore. If all goes properly, the economics of using multiple completions can be attractive; however, operating and workover costs can be quite high. These operational factors must be considered when considering multiple completions.

Alternate completions

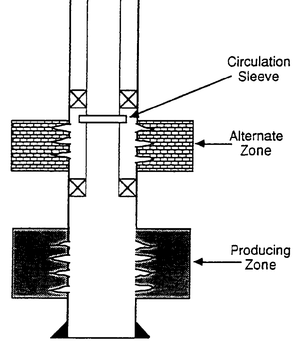

Alternate completions are used to allow inexpensive recompletions. Normally, a single interval is completed and produced to abandonment and then, using wireline tools, the lower interval is isolated and the upper interval opened to production (Figure 6). Alternate completions eliminate the need for costly workovers using rigs. It is possible to have a dual well with two alternate completions; however, as the completion gets more complex, more problems will occur. Alternate completions are used in areas where workover costs by conventional methods can be quite high. The most common use of alternate completions is offshore.

Slim hole completions

In certain reservoirs, the economic value of the reserves does not justify the expenditures of normal completion methods. An example of such a reservoir would be a series of thin, small lenticular dry gas intervals. Under certain conditions, the reservoir might not warrant the use of large production casing and tubing to produce the gas. For such reservoirs, slim hole completion techniques might be justified in which small pipe, such as 4-1/2-in. or 2-7/8-in. casing, is run and cemented in the wellbore. This small casing serves as the tubing and casing for the wellbore. This completion practice is used to minimize completion costs and should be used only for wells that are expected to have short producing lives and that do not require artificial lift.

Special Considerations for Producing and Injection Wells

The completion technique applied to a well depends on whether the well is a producing well or an injection well. For a producing well, the number of different reservoirs that may eventually be produced is significant. A decision must be made on whether a single or multiple completion will be made. One should be aware of stimulation treatments that may be required or the possible need for artificial lift equipment to produce fluids from the wellbore. Information on Christmas trees, [[[tubing spool]]s, packers, and downhole equipment needed to produce the well should be carefully designed and included in the completion program.

If a well is to be an injection well, one should be aware of the intervals that will require completion for the injection of fluids. The engineer should have an idea of the anticipated injection rates and pressure that will influence the design of the completion program. Extra effort should be made to ensure that the casing, tubing, wellhead, and cement programs are carefully designed and that the mechanical condition of the well during completion is excellent.

See also

External links

- Well Completions: Part 9. Production Engineering Methods — in AAPG Datapages