Vibro-sesismic to increasing the production rate of coal bed methane

| Wiki Write-Off Entry | |

|---|---|

| |

| Student Chapter | Universitas Gadjah Mada |

| Competition | June 2015 |

Coal bed methane

Coal bed methane (CBM) is a gas contained in coal layer. This gas is a fraction of coal bed gas (CBG), natural gas that produced from a coal layer. There are some others gasses that also contained in a coal layer, such as Carbon dioxide (CO2), Nitrogen (N2), and water (H2O) (Thomas, 2002)

The gas in a coal produced during the coalification process, that is the process of organic material change into peat, lignit, subbituminous, bituminous, till antrachite, as the influenced of pressure and temperature.

Porosity and permeability

Porosity is the space that exist within rocks or materials, meanwhile pearmebility is the capacity of pore material to let fluida flow.When the porosity increase, the pearmeability will also increase, and the production result will increase.

Vibroseismic theory and vibration effect

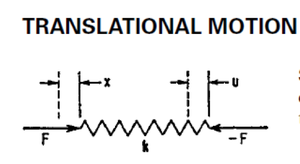

Vibration system is medium to save potential energy . this system have capability to save kinetic energy (massa or inertia). Vibration system involve ac-dc transfer energy beetwen potential and kinetic shape. In dimmed system some energy will be wrapped in each vibration cycle and must reaplacement from eksternal source, if the stabil vibration is hold. Although single pysic stucture can save kinetic and potential energy and can remove the energy. In translation move, replacement is distance, rotation as an angle move.[2]

In result of study analysts in laboratorium about core syntesis, vibration stimulation can repair the characteristic of rock physic that increase the porocity (φ) until 15.3% and absolute pearmeability (kabs) until 2.2% and decrease saturated oil remain (Sor) until 53.6%. From the result above need to do the reasearch that analysts the effect of vibration frequencyand pressure about porosity (φ), Kabs and Sor in cornfield.[3]

The analysts use the Hasler Permeameter tool with modification with vibrator. First model that designed with vibrator place above the core holder according vertical vibration direction. Meanwhile second model with vibrator that place beside core holder with horizontal vibration direction and direction beetwen vibrator and core holder closer than the first model. From the result of laboratorium study with second model tools in 15 core in the field, find that the the porocity before vibration is 4.84%-26.73% and after the vibration the porosity increase until 53.9% with average 36.6%. Kabs data before vibration is 231.46 m – 1113.59 mD and after vibration can reach 54.1% with average 39.4%. Sor Data before vibration is 0.15%-0.57%. and after vibration can reacht decrease Sor untul 68% with average 66.1 %. From the result above, there is the same result beetwen sysntesis core and field core that give the image about the same changing pattern in rock pysical properties (φ, kabs and Sor) because the effect of vibration stimulation with increase of porosity and kabs and the decrease of Sor. The effect of pressure in vibration stimulation make the system is confined, and the direction effect from the vibration source about core holder can as effective as radius from vibrator strength.[3]

In this era, the technology of vibroseismic can be useful in research that do in teoritic or laboratorium, aplication in field, and to predict the performance in the future that relate with economic evaluation. If mechanism that happen in reservoar applied in vibroseismic technology, there is a possibility to increase the production rate. But, the rate of success aplication in field cannot give the justification of description about mechanism yet (Ariadi et al., 2005)

On the otherhand, the generally term in oil industry before the application of a technology . firstly, the prediction of the work wether technically or economically have to be done. In order to do the prediction step several method will be needed such as Decline Curve Analysis, laboratory research or reservoir simulation. But, until now there are no such prediction method that accepted by the oil industry, at this level of knowledge, empirical approachment is the most suitable method of the field prediction. There is also a prediction method that has been recommended by the russian researcher (Institute of the Eart Physics and Institute of Oil and Gas Research below Russian Academy Society) based on previous datas of production and water cut. After that, this method is being examined, evaluated and then proposed to more reliable method.[4]

Step of experiment

From previous study indicated that vibro seismic can effect the permeability of coal. Here is the steps of the analyzing vibro seismic effect on coal permeability :

- Install and design the vibroseismic

- Measure the dimension of the core, and measure the initial porosity using Utilizing UltraPoreTM 300 Helium piknometer aparature systemMengukur permeabilitas absolut (kabs) menggunakan alat UltraPermTM400.

- Vibrate and inject nitrogen gas to the core of samples

- Measure the porosity and permeability absolute after vibrated

- Input the data of reservoir into reservoir model and various permeability before and after the vibration

The result of experiment

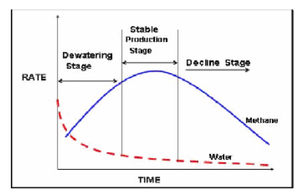

The Mechanism of gas production in a Coalbed Methane (CBM) Reservoir is different from the conventional gas reservoir in general. The CBM gases are adsorbed in a layer within the coal’s matrix (seam) and contain water inside of the crack. So that, CBM well will pass through three main phase of production, that are :

- Dewatering phase, during dewatering phase, the amount of water produced will exceed the amount of gas produced, but as the production continous, the amount of water produced will decline and the amount of gas produced will increase.

- Stable production phase, stable production phase will occur as the gas production is at maximum level and water production is at stable level.

- Declining production phase, and during the declining production phase, the amount methane produced will decrease until uneconomical stage of production.

The previous study indicate that vibration stimulation can change the coal properties, such as porosity and absolute permeability (kabs). Permeability is the main parameter of CBM reservoir in determining response of reservoir – reservoircoal – seam. The high value of permeability will increase the gas production rate related to the increase of gas desorption process speed.[4]

However, the optimum value of frequency will be needed to meet the maximum permeability, there are two ways to determine the optimum value of frequency, there are analytical method and experimental method. To determine the optimum value of frequency analytically, there is formula to count the exact value of optimum frequency, the formula is :

where:

- ω = optimum frequency (Hz)

- Cs=wave velocity shear (m/sec)3 .

- H = thick of formation (m)

And for experimental method, the value of optimum frequency is derived from laboratory research. Here is the example of using the experimental method. Given six samples of coal with the code S, A4, L, 3, A6, and I. The vibro seismic method is applied with various frequency’s value in each samples. And the value of permeability is measured using Hasler permeameter tool in each frequency. Tables below show the effect of vibro seismic to the change of permeability and porosity.

| k (md) | Amplitude (mv) | ||||||

|---|---|---|---|---|---|---|---|

| Initial | Vib. 1 | Vib. 2 | Vib. 3 | A1 | A2 | A3 | |

| S | 6.533 | 11.027 | 12.076 | 12.365 | 50 | 5 | 20 |

| A4 | 1.036 | 7.228 | 5.899 | 160.772 | 5 | 20 | 50 |

| L | 2.918 | 4.346 | 6.438 | 8.81 | 50 | 5 | 20 |

| 3 | 0.24 | 0.361 | 0.496 | 8.214 | 5 | 20 | 50 |

| A6 | 1.503 | 7.906 | 5.039 | 8.677 | 5 | 20 | 50 |

| I | 58.85 | 0.423 | 0.203 | 0.208 | 5 | 20 | 50 |

| k (md) | Amplitude (mv) | ||||||

|---|---|---|---|---|---|---|---|

| Initial | Vib. 1 | Vib. 2 | Vib. 3 | A1 | A2 | A3 | |

| S | 1.964 | 5.562 | 5.962 | 6.356 | 50 | 5 | 20 |

| A4 | 9.808 | 9.815 | 13.824 | 10.657 | 5 | 20 | 50 |

| L | 2.918 | 4.346 | 6.438 | 8.81 | 50 | 5 | 20 |

| 3 | 6.502 | 10.073 | 12.634 | 8.139 | 5 | 20 | 50 |

| A6 | 4.501 | 7.552 | 4.885 | 5.36 | 5 | 20 | 50 |

| I | 1.386 | 9.979 | 9.734 | 8.913 | 5 | 20 | 50 |

Based on vibro seismic effect on core sample where both frequency and amplitude act as the main parameter, shows that there is optimum condition that give maximum effect . And then the research continue with using nine various frequency and the final amount of each samples are counted in percent, there are :

| Frequency (Hz) | Porosity value (%) |

|---|---|

| 0 | 13 |

| 0.5 | 13 |

| 5 | 15 |

| 7 | 16.5 |

| 10 | 19 |

| 15 | 19 |

| 20 | 17 |

| 30 | 30 |

| 50 | 15 |

Based on the data, we know that the value of optimum frequency is 10 – 15 Hz[4]

Application

This vibroseismic effect to the permeability and porosity of the coal could be applicated to the production process of CBM, so that it can increase the production rate of CBM.

References

- ↑ Seidle, J., 2011, Fundamentals of Coalbed Methane Reservoir Engineering. Oklahoma: Pennwell Corporation.

- ↑ 2.0 2.1 Ralph, B., 1998, Basic Vibration Theory: London.

- ↑ 3.0 3.1 Ridaliani, O., T. Ariadji, and G. Handayani, 2005, Prediksi Perubahan Sifat Fisik Batuan Reservoir Dengan Studi Laboratorium Stimulasi Vibrasi Terhadap Contoh Batuan Lapangan Pada Berbagai Tekanan Overburden. Department Petroleum Engineering: Institut Teknologi Bandung.

- ↑ 4.0 4.1 4.2 4.3 4.4 Ariadji, T., H. Purwanto, and D. B. Scarboroug, 2005, Metode Peramalan Dan Evaluasi Keekonomian Teknologi Vibroseismik. Bandung: Petroleum Engineering Department.

Other sources

- Sukandarrumidi. 1995. Batubara dan Gambut. Yogyakarta: Gadjah Mada University Press.

- Sukandarrumidi. 2006. Batubara dan Gambut, Pengantar Teknologi Batubara Menuju Lingkungan Bersih. Yogyakarta: Gadjah Mada University Press.