Difference between revisions of "Pinedale field"

Cwhitehurst (talk | contribs) |

Cwhitehurst (talk | contribs) |

||

| (13 intermediate revisions by the same user not shown) | |||

| Line 12: | Line 12: | ||

| isbn = 9780891813873 | | isbn = 9780891813873 | ||

}} | }} | ||

| − | |||

| − | Figure 1 Location of the Pinedale field in the northern part of the Green River Basin just south of Pinedale, Wyoming. The field has a relatively small areal extent for its reserves, which are estimated at about 39 tcf of recoverable gas. | + | Pinedale field is located in the northern part of the Green River Basin in western Wyoming about 90 mi (145 km) southeast of Jackson, Wyoming, near the town of Pinedale ([[:File:M107FG1.jpg|Figure 1]]). It is one of the largest natural gas fields in the United States with ultimate recoverable reserves estimated to be about 39 trillion cubic feet (tcf) of methane-rich natural gas. Despite the huge gas reserves, the field's productive areal extent is relatively small as it is only about 30 mi (48 km) long and less than 5 mi (8 km) wide. The field covers an area of about 84 mi2 (220 km2). In this sense, it is a very concentrated gas resource. |

| + | |||

| + | [[File:M107FG1.jpg|thumb|300px|Figure 1 Location of the Pinedale field in the northern part of the Green River Basin just south of Pinedale, Wyoming. The field has a relatively small areal extent for its reserves, which are estimated at about 39 tcf of recoverable gas.]] | ||

Production at Pinedale comes from the Lance Pool, which is nearly 6000 ft (1800 m) thick and consists of multiple stacked discontinuous Upper Cretaceous Lance and upper Mesaverde sandstones and siltstones that were predominantly deposited by fluvial processes and are encased in shales and mudstones. The reservoir rocks in Pinedale field occur at depths of about 8500 to 14,500 ft (2600–4400 m) and are tight with fairly low porosity (mostly <10%) and very low (micro-Darcy) permeability. The tight nature of these reservoir rocks makes it difficult for gas to move laterally and vertically for significant distances. As a result, it is necessary to conduct multistage hydraulic fracturing in all of the field's wells to create pathways for the gas to enter the wellbores at commercial rates. | Production at Pinedale comes from the Lance Pool, which is nearly 6000 ft (1800 m) thick and consists of multiple stacked discontinuous Upper Cretaceous Lance and upper Mesaverde sandstones and siltstones that were predominantly deposited by fluvial processes and are encased in shales and mudstones. The reservoir rocks in Pinedale field occur at depths of about 8500 to 14,500 ft (2600–4400 m) and are tight with fairly low porosity (mostly <10%) and very low (micro-Darcy) permeability. The tight nature of these reservoir rocks makes it difficult for gas to move laterally and vertically for significant distances. As a result, it is necessary to conduct multistage hydraulic fracturing in all of the field's wells to create pathways for the gas to enter the wellbores at commercial rates. | ||

| − | The tight nature of the reservoir rocks at Pinedale begs the question: “What makes Pinedale such a prolific natural gas field?” The field has some unique geologic characteristics. Production is reliant on a complex interplay of geologic factors, including structure, reservoir sandstone and siltstone thickness, porosity development, permeability, and reservoir pressure, which are in turn related to sedimentary facies, diagenesis, water saturation and its control on relative permeability to gas, and possibly fracture size, density, and distribution. Added to these geologic parameters is the overprint of hydraulic fracture stimulation, which is done in every well. The Pinedale reservoir interval has about 1 billion cubic feet (bcf) of gas in place per acre. This high concentration of gas is in part due to the tremendous thickness (∼6000 ft, 1800 m) of the gas-saturated Lance and upper Mesaverde sections that comprise the Lance Pool. The gas volume is also enhanced by the overpressured character of the reservoir with pressures grading from about 0.57 psi per foot near the top of the Lance Pool up to 0.85 psi per foot near its base in parts of the field. In addition to the field's geologic characteristics, technological advances, particularly in drilling and hydraulic fracturing, have helped to release the gas trapped in the Lance Pool. Finally, high-density drilling, as dense as one well for five acres, has allowed for significantly improved recovery of natural gas from these tight reservoir rocks. | + | The tight nature of the reservoir rocks at Pinedale begs the question: “What makes Pinedale such a prolific natural gas field?” The field has some unique geologic characteristics. Production is reliant on a complex interplay of geologic factors, including structure, reservoir sandstone and siltstone thickness, porosity development, permeability, and reservoir pressure, which are in turn related to sedimentary facies, [[diagenesis]], water saturation and its control on relative permeability to gas, and possibly [[fracture]] size, density, and distribution. Added to these geologic parameters is the overprint of hydraulic fracture stimulation, which is done in every well. The Pinedale reservoir interval has about 1 billion cubic feet (bcf) of gas in place per acre. This high concentration of gas is in part due to the tremendous thickness (∼6000 ft, 1800 m) of the gas-saturated Lance and upper Mesaverde sections that comprise the Lance Pool. The gas volume is also enhanced by the overpressured character of the reservoir with pressures grading from about 0.57 psi per foot near the top of the Lance Pool up to 0.85 psi per foot near its base in parts of the field. In addition to the field's geologic characteristics, technological advances, particularly in drilling and hydraulic fracturing, have helped to release the gas trapped in the Lance Pool. Finally, high-density drilling, as dense as one well for five acres, has allowed for significantly improved recovery of natural gas from these tight reservoir rocks. |

| − | Pinedale field has had a long development history, which is described in detail in the following chapter by Kneller, Matheny, Albertus, and Riggs. The Pinedale anticline was first recognized from surface mapping in the early 1920s. The first well drilled on the anticline for hydrocarbons was the California Company's Government #1 drilled in 1939 and 1940. This well had gas shows in what is now recognized as the Lance Formation, but it tested at noncommercial rates and was eventually plugged and abandoned. Over the following 55 years, a number of other companies also attempted unsuccessfully to “crack the code” to produce economic quantities of natural gas from the micro-Darcy reservoir rocks within the anticline. However, it was not until the late 1990s when multistage hydraulic fracturing techniques that had been successfully employed in the nearby Jonah field, which lies just south of Pinedale field (Figure 1), were brought onto the anticline that commercial production was established. These techniques finally allowed Pinedale operators to stimulate sufficient volumes of this extremely tight rock to allow gas to flow at commercial rates. Simply stated, it was technological advancements and innovative thinking that led to the commercialization of the Pinedale field. | + | Pinedale field has had a long development history, which is described in detail in the following chapter by Kneller, Matheny, Albertus, and Riggs. The Pinedale anticline was first recognized from surface mapping in the early 1920s. The first well drilled on the anticline for hydrocarbons was the California Company's Government #1 drilled in 1939 and 1940. This well had gas shows in what is now recognized as the Lance Formation, but it tested at noncommercial rates and was eventually plugged and abandoned. Over the following 55 years, a number of other companies also attempted unsuccessfully to “crack the code” to produce economic quantities of natural gas from the micro-Darcy reservoir rocks within the anticline. However, it was not until the late 1990s when multistage hydraulic fracturing techniques that had been successfully employed in the nearby Jonah field, which lies just south of Pinedale field ([[:File:M107FG1.jpg|Figure 1]]), were brought onto the anticline that commercial production was established. These techniques finally allowed Pinedale operators to stimulate sufficient volumes of this extremely tight rock to allow gas to flow at commercial rates. Simply stated, it was technological advancements and innovative thinking that led to the commercialization of the Pinedale field. |

Today Pinedale is resource-wise and economically a very significant natural gas field. Through 2012, the field had produced 3.9 tcf of gas and 29.5 million barrels of condensate from 2200 wells. In 2012 alone, Pinedale produced 533 bcf (1.5 bcf per day), which is enough to heat 5.3 million homes, along with over 3.8 million barrels of condensate. This makes Pinedale not only the largest gas field in the state of Wyoming but also the second largest oil field. Today Pinedale has become a major part of America's energy supply, producing over 2% of the United States' demand for natural gas. | Today Pinedale is resource-wise and economically a very significant natural gas field. Through 2012, the field had produced 3.9 tcf of gas and 29.5 million barrels of condensate from 2200 wells. In 2012 alone, Pinedale produced 533 bcf (1.5 bcf per day), which is enough to heat 5.3 million homes, along with over 3.8 million barrels of condensate. This makes Pinedale not only the largest gas field in the state of Wyoming but also the second largest oil field. Today Pinedale has become a major part of America's energy supply, producing over 2% of the United States' demand for natural gas. | ||

| Line 33: | Line 34: | ||

The ability to operate year round within a concentrated development area benefits industry, the environment, the people of Wyoming, and wildlife. It provides continuity to operations that leads to efficient application of technology, which allows operators to drill more wells per rig with less emissions per well, and to fully develop the resource. It also makes it feasible to use the latest technologies to reduce emissions such as installing LGSs, applying selective catalytic reduction (SCR) devices to rig engines to reduce emissions of nitrogen oxides to near zero, and consolidating production facilities. Continuity of operations also promotes a stable workforce with steady employment and a consistent tax revenue stream for the state of Wyoming. | The ability to operate year round within a concentrated development area benefits industry, the environment, the people of Wyoming, and wildlife. It provides continuity to operations that leads to efficient application of technology, which allows operators to drill more wells per rig with less emissions per well, and to fully develop the resource. It also makes it feasible to use the latest technologies to reduce emissions such as installing LGSs, applying selective catalytic reduction (SCR) devices to rig engines to reduce emissions of nitrogen oxides to near zero, and consolidating production facilities. Continuity of operations also promotes a stable workforce with steady employment and a consistent tax revenue stream for the state of Wyoming. | ||

| − | + | <gallery mode=packed heights=200px widths=200px> | |

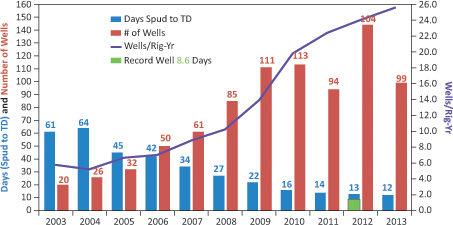

| + | M107FG2.jpg|{{figure number|2}}Average drill times from spud to attaining total depth (blue bars) for wells drilled by QEP in Pinedale field. With improved drill bits, mud systems, and crew efficiency, drill times decreased by more than 80% between 2003 and 2013. Also shown are the number of wells drilled each year (brown bars) and the wells per rig per year (purple line). The green box shows the record well drilled in just 8.6 days in 2012. Data in part from [http://media.corporate-ir.net/media_files/IROL/23/237732/QEP1Q13OpsSlides.pdf QEP Resources investor relations presentation.] | ||

| + | M107FG3.jpg|{{figure number|3}}Simultaneous operations being conducted in Pinedale field with drilling, [[fracking]], setting of surface pipe, and facilities installation all occurring concurrently. | ||

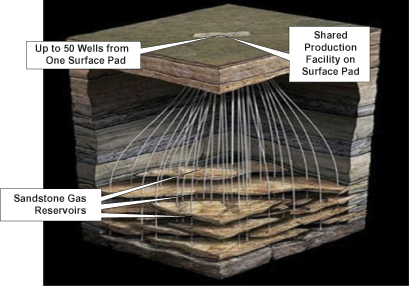

| + | M107FG4.jpg|{{figure number|4}}High-density pad drilling allows development of a large subsurface volume of the gas resource with minimal impact to the surface environment. | ||

| + | </gallery> | ||

| − | + | The continuity provided by year-round access led to significant performance improvements in drilling and completion efficiencies. Average drilling times have dropped from more than 60 days per well in the early 2000s to less than 12 days per well in 2013. In recent years, some wells have even been drilled to depths of over 14,000 ft (4300 m) in less than nine days ([[:File:M107FG2.jpg|Figure 2]]). | |

The decline in drill times can be attributed to a number of factors including fit-for-purpose rigs, improved drill-bit technology, drilling wells with oil-based mud instead of water-based mud, consistently trained and experienced crews, use of down-hole mud-motors and steerable assemblies, new slim-hole well designs, multiwell pad drilling, and removing steps from the critical path of the drilling rig. Similar performance gains have been seen on the completions side where wells once took more than a month to complete. Now a pair of wells can be completely fracked with over 20 frack stages per well within four or five days. These efficiencies have given Pinedale operators a cost advantage that has expanded the economic limits of the field and allowed for full field development through high density drilling. | The decline in drill times can be attributed to a number of factors including fit-for-purpose rigs, improved drill-bit technology, drilling wells with oil-based mud instead of water-based mud, consistently trained and experienced crews, use of down-hole mud-motors and steerable assemblies, new slim-hole well designs, multiwell pad drilling, and removing steps from the critical path of the drilling rig. Similar performance gains have been seen on the completions side where wells once took more than a month to complete. Now a pair of wells can be completely fracked with over 20 frack stages per well within four or five days. These efficiencies have given Pinedale operators a cost advantage that has expanded the economic limits of the field and allowed for full field development through high density drilling. | ||

| − | Simultaneous operations (SIMOPS) are also now being done by all the major operators in Pinedale field with drilling, hydraulic fracturing, and facilities installations occurring at the same time (Figure 3). In order to fully develop the resource, wells are being drilled on dense spacing of as little as five acres per well. This makes Pinedale field one of the first places with such high-density pad drilling. Well bores are gently S-shaped and are drilled on pads to reduce the surface disturbance, which allows the development of a relatively large subsurface volume from a relatively small surface area (Figure 4). | + | Simultaneous operations (SIMOPS) are also now being done by all the major operators in Pinedale field with drilling, hydraulic fracturing, and facilities installations occurring at the same time ([[:File:M107FG3.jpg|Figure 3]]). In order to fully develop the resource, wells are being drilled on dense spacing of as little as five acres per well. This makes Pinedale field one of the first places with such high-density pad drilling. Well bores are gently S-shaped and are drilled on pads to reduce the surface disturbance, which allows the development of a relatively large subsurface volume from a relatively small surface area ([[:File:M107FG4.jpg|Figure 4]]). |

| − | Figure | + | ==Pad drilling in pinedale field== |

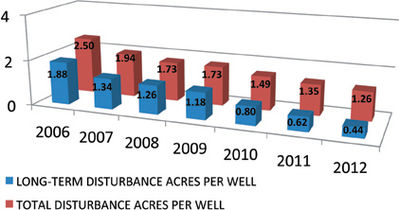

| + | [[File:M107FG5.jpg|thumb|400px|Figure 5 Total disturbance per well and long-term disturbance per well continue to decline with improved drilling techniques such as the pad drilling now being used to develop Pinedale field.]] | ||

| − | |||

| − | |||

| − | |||

High-density development is conducive to pad drilling. In Pinedale field, the operators drill gently S-shaped directional wells from central surface pads. This is a technology that was originally developed for drilling offshore wells from a central platform, but that is now being applied onshore. Wells are arranged in pods of two to eight wells on a pad. Up to 50 wells can be drilled on an individual pad so that the physical footprint of operations and wildlife habitat fragmentation are minimized. | High-density development is conducive to pad drilling. In Pinedale field, the operators drill gently S-shaped directional wells from central surface pads. This is a technology that was originally developed for drilling offshore wells from a central platform, but that is now being applied onshore. Wells are arranged in pods of two to eight wells on a pad. Up to 50 wells can be drilled on an individual pad so that the physical footprint of operations and wildlife habitat fragmentation are minimized. | ||

| − | Pad drilling along with timely reclamation has allowed all Pinedale field operators to reduce disturbance of the land. As field development has progressed and the number of wells per pad increased, the disturbance per well has continued to decline. Surface disturbance per well is now less than one acre on some multiwell pads (Figure 5) | + | Pad drilling along with timely reclamation has allowed all Pinedale field operators to reduce disturbance of the land. As field development has progressed and the number of wells per pad increased, the disturbance per well has continued to decline. Surface disturbance per well is now less than one acre on some multiwell pads ([[:File:M107FG5.jpg|Figure 5]]). |

| − | |||

| − | |||

==Environmental concerns== | ==Environmental concerns== | ||

| − | Pinedale operators have addressed a number of environmental concerns through new technologies and best management practices. Pinedale operators take air quality issues, particularly ozone, very seriously. Industry deals with ozone by reducing the volumes of volatile organic carbons (VOCs) and nitrous oxide (NOx) emissions, both of which are precursors to ozone formation. Pinedale operators had installed SCR devices on all of their rig engines by year-end 2011 to reduce NOx emissions, and, as previously mentioned, they also reduced VOCs by installing LGSs, which eliminated truck traffic, dust pollution, and associated emissions. These systems also eliminate the need for storage tanks and their associated VOCs. As well, the LGS has allowed operators to recycle their produced water and reuse it in fracking operations. This reduces the amount of water taken from local freshwater aquifers. Furthermore, in Pinedale operators do flareless completions. Rather than flaring gas during completions, they route the gas to sales during flowback, thereby eliminating emissions. And on days where Wyoming's Department of Environmental Quality determines that atmospheric conditions are ripe for ozone formation, Pinedale operators cancel all nonessential operations. The concentrated nature of production operations in the field along with the ability to conduct limited year-round activity make it feasible to consolidate facilities and employ these advanced emission-cutting technologies. | + | Pinedale operators have addressed a number of environmental concerns through new technologies and best management practices. Pinedale operators take air quality issues, particularly ozone, very seriously. Industry deals with ozone by reducing the volumes of volatile organic carbons (VOCs) and nitrous oxide (NOx) emissions, both of which are precursors to ozone formation. Pinedale operators had installed SCR devices on all of their rig engines by year-end 2011 to reduce NOx emissions, and, as previously mentioned, they also reduced VOCs by installing LGSs, which eliminated truck traffic, dust pollution, and associated emissions. These systems also eliminate the need for storage tanks and their associated VOCs. As well, the LGS has allowed operators to recycle their produced water and reuse it in [[fracking]] operations. This reduces the amount of water taken from local freshwater aquifers. Furthermore, in Pinedale operators do flareless completions. Rather than flaring gas during completions, they route the gas to sales during flowback, thereby eliminating emissions. And on days where Wyoming's Department of Environmental Quality determines that atmospheric conditions are ripe for ozone formation, Pinedale operators cancel all nonessential operations. The concentrated nature of production operations in the field along with the ability to conduct limited year-round activity make it feasible to consolidate facilities and employ these advanced emission-cutting technologies. |

Pinedale field is a giant natural gas resource with unique geologic characteristics. Because of the advanced application of technology and innovative thinking, Pinedale has become the model for modern tight gas development in the United States and throughout the world. It is an efficient “gas factory” where the attention is on fully developing the natural gas resource economically and effectively, without waste, in a safe manner, with focus on the environment, wildlife, and the socioeconomic benefits for the people of the area. Many of the innovative practices developed in Pinedale have been and are being applied elsewhere around the world. | Pinedale field is a giant natural gas resource with unique geologic characteristics. Because of the advanced application of technology and innovative thinking, Pinedale has become the model for modern tight gas development in the United States and throughout the world. It is an efficient “gas factory” where the attention is on fully developing the natural gas resource economically and effectively, without waste, in a safe manner, with focus on the environment, wildlife, and the socioeconomic benefits for the people of the area. Many of the innovative practices developed in Pinedale have been and are being applied elsewhere around the world. | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

==Conclusions== | ==Conclusions== | ||

Technology and innovative thinking, mainly during the past 15 years, have driven Pinedale field's development and unlocked a giant domestic energy resource in the United States. These techniques have benefitted all of the following: (1) the oil and gas industry, which through enhanced geologic understanding, better hydraulic fracturing techniques, reduced drilling times and improved operational efficiency has been able to convert what until the 1990s had been a subeconomic play unsuccessfully chased by dozens of companies into one of the most commercially successful fields; (2) wildlife, due to the well thought out regulations and field development plans that have led to geographically focused human and drilling activities and reduced habitat fragmentation; (3) the environment through water recycling, reduced noxious air emissions, and a network of pipelines for fluid transport; (4) safety by lowering the total recordable incidence rate through pad drilling, continuous operations, and long-term employment on the drill rigs; and (5) ultimately, the people of Wyoming through the millions of dollars spent for field development, the hundreds of jobs created both directly and indirectly by all the work done in the Pinedale field area, and the steady (and large!) stream of tax revenue that the field's production has provided to the state. | Technology and innovative thinking, mainly during the past 15 years, have driven Pinedale field's development and unlocked a giant domestic energy resource in the United States. These techniques have benefitted all of the following: (1) the oil and gas industry, which through enhanced geologic understanding, better hydraulic fracturing techniques, reduced drilling times and improved operational efficiency has been able to convert what until the 1990s had been a subeconomic play unsuccessfully chased by dozens of companies into one of the most commercially successful fields; (2) wildlife, due to the well thought out regulations and field development plans that have led to geographically focused human and drilling activities and reduced habitat fragmentation; (3) the environment through water recycling, reduced noxious air emissions, and a network of pipelines for fluid transport; (4) safety by lowering the total recordable incidence rate through pad drilling, continuous operations, and long-term employment on the drill rigs; and (5) ultimately, the people of Wyoming through the millions of dollars spent for field development, the hundreds of jobs created both directly and indirectly by all the work done in the Pinedale field area, and the steady (and large!) stream of tax revenue that the field's production has provided to the state. | ||

Latest revision as of 17:13, 29 January 2016

| Pinedale Field: Case Study of a Giant Tight Gas Sandstone Reservoir | |

| |

| Series | Memoirs |

|---|---|

| Chapter | The Significance of the Pinedale Field |

| Author | Thomas Meyer and Mark Longman |

| Link | Web page |

| PDF file (requires access) | |

| Store | AAPG Store |

Pinedale field is located in the northern part of the Green River Basin in western Wyoming about 90 mi (145 km) southeast of Jackson, Wyoming, near the town of Pinedale (Figure 1). It is one of the largest natural gas fields in the United States with ultimate recoverable reserves estimated to be about 39 trillion cubic feet (tcf) of methane-rich natural gas. Despite the huge gas reserves, the field's productive areal extent is relatively small as it is only about 30 mi (48 km) long and less than 5 mi (8 km) wide. The field covers an area of about 84 mi2 (220 km2). In this sense, it is a very concentrated gas resource.

Production at Pinedale comes from the Lance Pool, which is nearly 6000 ft (1800 m) thick and consists of multiple stacked discontinuous Upper Cretaceous Lance and upper Mesaverde sandstones and siltstones that were predominantly deposited by fluvial processes and are encased in shales and mudstones. The reservoir rocks in Pinedale field occur at depths of about 8500 to 14,500 ft (2600–4400 m) and are tight with fairly low porosity (mostly <10%) and very low (micro-Darcy) permeability. The tight nature of these reservoir rocks makes it difficult for gas to move laterally and vertically for significant distances. As a result, it is necessary to conduct multistage hydraulic fracturing in all of the field's wells to create pathways for the gas to enter the wellbores at commercial rates.

The tight nature of the reservoir rocks at Pinedale begs the question: “What makes Pinedale such a prolific natural gas field?” The field has some unique geologic characteristics. Production is reliant on a complex interplay of geologic factors, including structure, reservoir sandstone and siltstone thickness, porosity development, permeability, and reservoir pressure, which are in turn related to sedimentary facies, diagenesis, water saturation and its control on relative permeability to gas, and possibly fracture size, density, and distribution. Added to these geologic parameters is the overprint of hydraulic fracture stimulation, which is done in every well. The Pinedale reservoir interval has about 1 billion cubic feet (bcf) of gas in place per acre. This high concentration of gas is in part due to the tremendous thickness (∼6000 ft, 1800 m) of the gas-saturated Lance and upper Mesaverde sections that comprise the Lance Pool. The gas volume is also enhanced by the overpressured character of the reservoir with pressures grading from about 0.57 psi per foot near the top of the Lance Pool up to 0.85 psi per foot near its base in parts of the field. In addition to the field's geologic characteristics, technological advances, particularly in drilling and hydraulic fracturing, have helped to release the gas trapped in the Lance Pool. Finally, high-density drilling, as dense as one well for five acres, has allowed for significantly improved recovery of natural gas from these tight reservoir rocks.

Pinedale field has had a long development history, which is described in detail in the following chapter by Kneller, Matheny, Albertus, and Riggs. The Pinedale anticline was first recognized from surface mapping in the early 1920s. The first well drilled on the anticline for hydrocarbons was the California Company's Government #1 drilled in 1939 and 1940. This well had gas shows in what is now recognized as the Lance Formation, but it tested at noncommercial rates and was eventually plugged and abandoned. Over the following 55 years, a number of other companies also attempted unsuccessfully to “crack the code” to produce economic quantities of natural gas from the micro-Darcy reservoir rocks within the anticline. However, it was not until the late 1990s when multistage hydraulic fracturing techniques that had been successfully employed in the nearby Jonah field, which lies just south of Pinedale field (Figure 1), were brought onto the anticline that commercial production was established. These techniques finally allowed Pinedale operators to stimulate sufficient volumes of this extremely tight rock to allow gas to flow at commercial rates. Simply stated, it was technological advancements and innovative thinking that led to the commercialization of the Pinedale field.

Today Pinedale is resource-wise and economically a very significant natural gas field. Through 2012, the field had produced 3.9 tcf of gas and 29.5 million barrels of condensate from 2200 wells. In 2012 alone, Pinedale produced 533 bcf (1.5 bcf per day), which is enough to heat 5.3 million homes, along with over 3.8 million barrels of condensate. This makes Pinedale not only the largest gas field in the state of Wyoming but also the second largest oil field. Today Pinedale has become a major part of America's energy supply, producing over 2% of the United States' demand for natural gas.

Significance of the pinedale field

Pinedale is special not only because of its geological characteristics and its size but also because of the efficiency in operations that the field's operators have achieved. As a result, it has become the model for tight gas sandstone development in fields around the world. In addition, Pinedale has been groundbreaking on environmental and regulatory issues, particularly in the creative ways that industry has worked with government and environmental regulators to shape policy and regulations that benefit both industry and the environment. Pinedale became the first major greenfield development in the United States in an environmentally sensitive area with thousands of wells planned on hundreds of pads. Furthermore, the field was only 10% developed when the Supplemental Environmental Impact Statement (SEIS) process was started in 2005.

The SEIS was one of the first Bureau of Land Management (BLM) documents built around the concept of adaptive management, meaning that the rules could be adjusted to reflect actual on-the-ground outcomes. Pinedale was also one of the first examples where companies voluntarily acted in a coordinated way for the benefit of both the environment and industry. This was truly unusual given that, other than Ultra Petroleum, no single operator had an interest in the other operators' wells.

A very innovative regulatory plan granting “limited year-round access” was cooperatively developed by the BLM and Pinedale operators and incorporated in the 2008 Record of Decision to the SEIS in exchange for environmental mitigations that cost the three major operators in the field (Ultra Petroleum, Questar/QEP Resources, and Shell Western E & P) over $1 billion. These mitigations included focusing year-round operations on pads within concentrated development areas, reducing air emissions, and installation of liquids gathering systems (LGSs) to reduce truck traffic to and from the anticline. Limited year-round access allowed Pinedale operators to operate within focused development areas throughout the year. Within these concentrated development areas, seasonal stipulations for big game animals and sage grouse are waived. Development progresses in a stipulated development pattern and reclamation is done after pads are fully developed. In each of the defined development areas, set development patterns exist. This ensures that at any one time, 92% of the anticline has no development activity. It also benefits wildlife in that it reduces habitat fragmentation by focusing operations, maintaining corridors for wildlife migration, and shortening the time for full field development. In addition, it leaves large areas of contiguous habitat available for migration corridors and places for animals to forage, rest, and reproduce.

The ability to operate year round within a concentrated development area benefits industry, the environment, the people of Wyoming, and wildlife. It provides continuity to operations that leads to efficient application of technology, which allows operators to drill more wells per rig with less emissions per well, and to fully develop the resource. It also makes it feasible to use the latest technologies to reduce emissions such as installing LGSs, applying selective catalytic reduction (SCR) devices to rig engines to reduce emissions of nitrogen oxides to near zero, and consolidating production facilities. Continuity of operations also promotes a stable workforce with steady employment and a consistent tax revenue stream for the state of Wyoming.

Figure 2 Average drill times from spud to attaining total depth (blue bars) for wells drilled by QEP in Pinedale field. With improved drill bits, mud systems, and crew efficiency, drill times decreased by more than 80% between 2003 and 2013. Also shown are the number of wells drilled each year (brown bars) and the wells per rig per year (purple line). The green box shows the record well drilled in just 8.6 days in 2012. Data in part from QEP Resources investor relations presentation.

Figure 3 Simultaneous operations being conducted in Pinedale field with drilling, fracking, setting of surface pipe, and facilities installation all occurring concurrently.

The continuity provided by year-round access led to significant performance improvements in drilling and completion efficiencies. Average drilling times have dropped from more than 60 days per well in the early 2000s to less than 12 days per well in 2013. In recent years, some wells have even been drilled to depths of over 14,000 ft (4300 m) in less than nine days (Figure 2).

The decline in drill times can be attributed to a number of factors including fit-for-purpose rigs, improved drill-bit technology, drilling wells with oil-based mud instead of water-based mud, consistently trained and experienced crews, use of down-hole mud-motors and steerable assemblies, new slim-hole well designs, multiwell pad drilling, and removing steps from the critical path of the drilling rig. Similar performance gains have been seen on the completions side where wells once took more than a month to complete. Now a pair of wells can be completely fracked with over 20 frack stages per well within four or five days. These efficiencies have given Pinedale operators a cost advantage that has expanded the economic limits of the field and allowed for full field development through high density drilling.

Simultaneous operations (SIMOPS) are also now being done by all the major operators in Pinedale field with drilling, hydraulic fracturing, and facilities installations occurring at the same time (Figure 3). In order to fully develop the resource, wells are being drilled on dense spacing of as little as five acres per well. This makes Pinedale field one of the first places with such high-density pad drilling. Well bores are gently S-shaped and are drilled on pads to reduce the surface disturbance, which allows the development of a relatively large subsurface volume from a relatively small surface area (Figure 4).

Pad drilling in pinedale field

High-density development is conducive to pad drilling. In Pinedale field, the operators drill gently S-shaped directional wells from central surface pads. This is a technology that was originally developed for drilling offshore wells from a central platform, but that is now being applied onshore. Wells are arranged in pods of two to eight wells on a pad. Up to 50 wells can be drilled on an individual pad so that the physical footprint of operations and wildlife habitat fragmentation are minimized.

Pad drilling along with timely reclamation has allowed all Pinedale field operators to reduce disturbance of the land. As field development has progressed and the number of wells per pad increased, the disturbance per well has continued to decline. Surface disturbance per well is now less than one acre on some multiwell pads (Figure 5).

Environmental concerns

Pinedale operators have addressed a number of environmental concerns through new technologies and best management practices. Pinedale operators take air quality issues, particularly ozone, very seriously. Industry deals with ozone by reducing the volumes of volatile organic carbons (VOCs) and nitrous oxide (NOx) emissions, both of which are precursors to ozone formation. Pinedale operators had installed SCR devices on all of their rig engines by year-end 2011 to reduce NOx emissions, and, as previously mentioned, they also reduced VOCs by installing LGSs, which eliminated truck traffic, dust pollution, and associated emissions. These systems also eliminate the need for storage tanks and their associated VOCs. As well, the LGS has allowed operators to recycle their produced water and reuse it in fracking operations. This reduces the amount of water taken from local freshwater aquifers. Furthermore, in Pinedale operators do flareless completions. Rather than flaring gas during completions, they route the gas to sales during flowback, thereby eliminating emissions. And on days where Wyoming's Department of Environmental Quality determines that atmospheric conditions are ripe for ozone formation, Pinedale operators cancel all nonessential operations. The concentrated nature of production operations in the field along with the ability to conduct limited year-round activity make it feasible to consolidate facilities and employ these advanced emission-cutting technologies.

Pinedale field is a giant natural gas resource with unique geologic characteristics. Because of the advanced application of technology and innovative thinking, Pinedale has become the model for modern tight gas development in the United States and throughout the world. It is an efficient “gas factory” where the attention is on fully developing the natural gas resource economically and effectively, without waste, in a safe manner, with focus on the environment, wildlife, and the socioeconomic benefits for the people of the area. Many of the innovative practices developed in Pinedale have been and are being applied elsewhere around the world.

Conclusions

Technology and innovative thinking, mainly during the past 15 years, have driven Pinedale field's development and unlocked a giant domestic energy resource in the United States. These techniques have benefitted all of the following: (1) the oil and gas industry, which through enhanced geologic understanding, better hydraulic fracturing techniques, reduced drilling times and improved operational efficiency has been able to convert what until the 1990s had been a subeconomic play unsuccessfully chased by dozens of companies into one of the most commercially successful fields; (2) wildlife, due to the well thought out regulations and field development plans that have led to geographically focused human and drilling activities and reduced habitat fragmentation; (3) the environment through water recycling, reduced noxious air emissions, and a network of pipelines for fluid transport; (4) safety by lowering the total recordable incidence rate through pad drilling, continuous operations, and long-term employment on the drill rigs; and (5) ultimately, the people of Wyoming through the millions of dollars spent for field development, the hundreds of jobs created both directly and indirectly by all the work done in the Pinedale field area, and the steady (and large!) stream of tax revenue that the field's production has provided to the state.