Mudlogging: equipment, services, and personnel

| Development Geology Reference Manual | |

| |

| Series | Methods in Exploration |

|---|---|

| Part | Wellsite methods |

| Chapter | Mudlogging: equipment, services, and personnel |

| Author | Alun Whittaker |

| Link | Web page |

| Store | AAPG Store |

Mudlogging, sometimes called hydrocarbon logging or physical formation logging, involves the monitoring and recording of a variety of data related to the borehole and to the drilling process. Mudlogging incorporates gas analysis and cuttings data with drilling information to build a continuous formation evaluation record as the well is being drilled. Equipment and services for mudlogging can range from simple monitoring to integrated computer modeling of the wellsite and borehole environment.

Equipment

Standard equipment

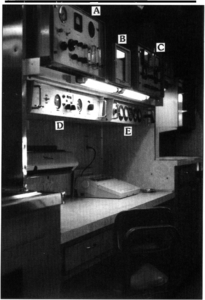

The minimum complement of equipment for basic mudlogging is listed here. Figure 1 shows much of this equipment in a typical mudiogger's work area.

- Gas extraction—An automatic gas trap is located in the return mudstream for continuous gas extraction (see chapter on “Mudlogging: Gas Extraction and Monitoring”).

- Vacuum system—A vacuum pump, pressure regulators, flow meters, filters, and dryers maintain uniform gas sample flow rate and composition from the gas trap and blender. This system includes a pressure and flow alarm and purge system to detect vacuum system blockage or leaks.

- Total gas detector—Hot wire, flame ionization, or infrared detectors are acceptable for total gas detection.

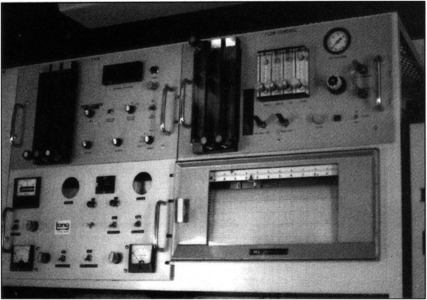

- Chromatograph—An automatic gas chromatograph is equipped with a flame ionization detector (FID) or infrared detector capable of accepting samples from either the gas trap or blender (Figures 1 and 2).

- Gas calibration—A gas calibration system injects known single and mixed gases into the total gas detector and chromatograph in a range of concentrations for calibration.

- Blender—A blender agitates and grinds a discrete sample of mud and cuttings and extracts the released gas for measurement.

- Depth and rate of penetration monitor—A sensor independent of the drilling system is capable of detecting changes in depth and compensating for rig motion offshore (Figure 1).

- Pump rate counter—A pump stroke counter is needed for each mud pump

- Mud pit level monitor—Continuous monitoring of mud pit level(s) and rig motion-compensated volume is necessary

- Chart recording—A continuous analog chart recording is made of all logged data.

- Mud test kit—This kit contains equipment to perform routine drilling fluid analyses and titrations.

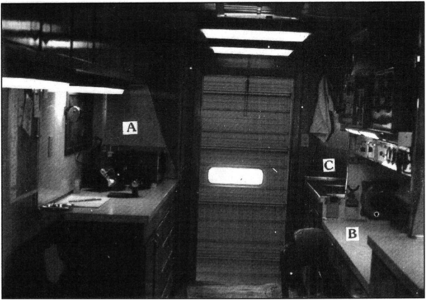

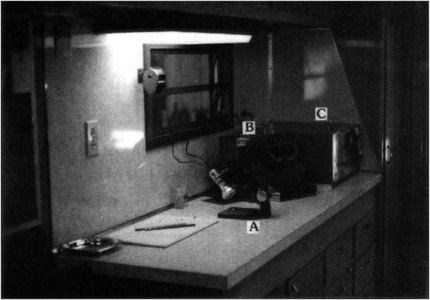

- Sample processing equipment—This equipment is used for catching, sieving, preparing, and testing lithology, mineralogy, and oil content in cuttings (Figures 3 and 4).

- Optical equipment—A stereomicroscope is equipped for use with natural and ultraviolet light.

- hog production equipment—A typewriter, plotter, and copy system are needed for log reproduction.

Additional equipment may be needed to perform special on-site analyses.

Logging unit equipment

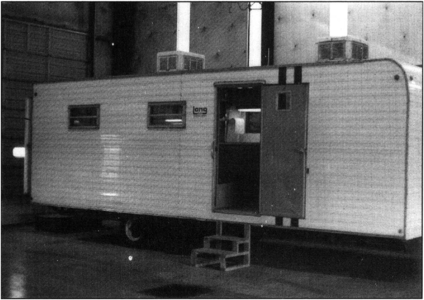

The equipment used in mudlogging is housed in a portable “unit” or small trailer (Figure 5). Most mudlogging units have similar physical layouts. Electronic instruments are typically housed at one end of the unit, while a sample handling area is along one wall and a work area along another wall (Figure 3). Sleeping and eating facilities may also be housed at the far end of the unit.

For extremely hazardous locations, mudlogging units are constructed of steel plate, pressurized to prevent gas entry, and equipped with insulating fireproof and explosion-proof components.

Services

Standard services

Standard mudlogging services include the following:

- Monitoring rate of penetration (including factors that can affect ROP response, such as changes in weight on bit, revolutions per minute, and pump pressure) (see Rate of penetration)

- Monitoring of drilling activity

- Monitoring of gas (see Mudlogging: gas extraction and monitoring)

- Drill cuttings analysis (including lithology breakdown and observed versus interpreted lithology) (see Mudlogging: drill cuttings analysis)

- Show evaluation (factoring in data such as ROP, lithology, cut type, and intensity)

- Safety considerations, such as checking for flow and sudden gas increases

Specialized services

In addition to the standard services, certain specialized mudlogging services can be provided:

- Pressure detection

- Geochemical analyses (such as cation exchange capacity, calcimetry, and pyroanalysis)

- Petrophysical analysis

- Measurements while drilling (MWD)

- Communications

Personnel

Standard mudlogging is generally performed by a two-person crew that works 12-hr rotating shifts, ensuring continuous monitoring of wellsite activities. The on-tour logger catches, prepares, and analyses the drill cuttings and records this information along with other data from the instrument panel and rig drilling records.

During periods of rapid drilling or when multiple special analyses are run, an additional logger or sample catcher is often added to each tour.

In some mature exploitation areas, companies will hire one mudlogging contractor to monitor several wells at a time. In such cases, rig crews are required to catch cuttings samples for later analysis by the logger. These samples are often caught as time allows and are not as useful as cuttings that have been systematically caught and lagged (see Wellsite math).

See also

- Drilling problems

- Mudlogging: drill cuttings analysis

- Introduction to wellsite methods

- Wellbore trajectory

- Conventional coring

- Drilling fluid

- Land rigs

- Rig personnel

- Wellsite math

- Core handling

- Core alteration and preservation

- Wellsite safety

- Sidewall coring

- Show evaluation

- Rate of penetration

- Mudlogging: the mudlog

- Well planning

- Pressure detection

- Drill stem testing

- Measurement while drilling

- Offshore rigs

- Fishing

- Core orientation

- Mudlogging: gas extraction and monitoring