Difference between revisions of "Sandstone permeability prediction from texture"

Cwhitehurst (talk | contribs) |

Cwhitehurst (talk | contribs) |

||

| Line 47: | Line 47: | ||

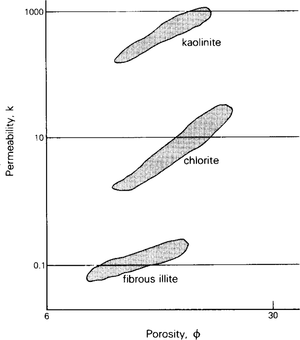

Pore-bridging clays, like [[illite]], decrease porosity slightly but can destroy sandstone [[permeability]]. Discrete particle clay, like [[kaolinite]], lowers [[porosity]] and permeability only slightly. [[:file:predicting-reservoir-system-quality-and-performance_fig9-61.png|Figure 2]] compares porosity-permeability relationships for kaolinite-, [[chlorite]]-, and illite-cemented sandstones. Note there is no significant change in porosities, but permeabilities range over four orders of magnitude. | Pore-bridging clays, like [[illite]], decrease porosity slightly but can destroy sandstone [[permeability]]. Discrete particle clay, like [[kaolinite]], lowers [[porosity]] and permeability only slightly. [[:file:predicting-reservoir-system-quality-and-performance_fig9-61.png|Figure 2]] compares porosity-permeability relationships for kaolinite-, [[chlorite]]-, and illite-cemented sandstones. Note there is no significant change in porosities, but permeabilities range over four orders of magnitude. | ||

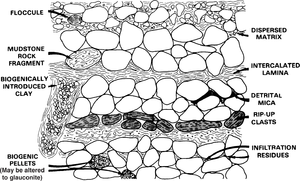

| − | [[file:predicting-reservoir-system-quality-and-performance_fig9-62.png|thumb|300px|{{figure number|3}}After Neasham.<ref name=ch09r40>Neasham, J. W., 1977, The morphology of dispersed clay in sandstone reservoirs and its effect on sandstone shaliness, pore space, and fluid flow properties: Proceedings of the SPE Annual Meeting, October 9–12, paper SPE-6858.</ref> Copyright: SPE.]] | + | [[file:predicting-reservoir-system-quality-and-performance_fig9-62.png|thumb|300px|{{figure number|3}}Pore lining and discrete particle clays. After Neasham.<ref name=ch09r40>Neasham, J. W., 1977, The morphology of dispersed clay in sandstone reservoirs and its effect on sandstone shaliness, pore space, and fluid flow properties: Proceedings of the SPE Annual Meeting, October 9–12, paper SPE-6858.</ref> Copyright: SPE.]] |

[[:file:predicting-reservoir-system-quality-and-performance_fig9-62.png|Figure 3]] shows pore lining and discrete particle clays that decrease porosity and permeability only slightly in contrast to pore-bridging clays, which decrease porosity slightly but substantially lower permeability. | [[:file:predicting-reservoir-system-quality-and-performance_fig9-62.png|Figure 3]] shows pore lining and discrete particle clays that decrease porosity and permeability only slightly in contrast to pore-bridging clays, which decrease porosity slightly but substantially lower permeability. | ||

Revision as of 15:37, 4 September 2014

| Exploring for Oil and Gas Traps | |

| |

| Series | Treatise in Petroleum Geology |

|---|---|

| Part | Predicting the occurrence of oil and gas traps |

| Chapter | Predicting reservoir system quality and performance |

| Author | Dan J. Hartmann, Edward A. Beaumont |

| Link | Web page |

| Store | AAPG Store |

Pore type, pore geometry, and fluid properties are critical factors affecting permeability. Sandstone texture directly affects pore type and geometry. Knowing what textures and fluids to expect, as well as what authigenic clays might be present, can help us predict permeability.

Effects of pore type and geometry

Pore type, defined by pore throat size (i.e., macroporosity), directly controls rock permeability. Pore throat size limits flow capacity. Pore geometry also affects permeability, but not as much. The rougher the surface of the pore, the more difficult for fluid to flow through the pore and the lower the permeability.

Effects of texture

Sandstone texture affects permeability as follows:

- Decreasing grain size decreases permeability.

- Increasing grain sorting increases permeability.

- Increasing grain rounding increases permeability.

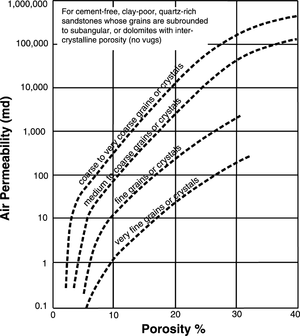

Figure 1 shows how grain size affects permeability and porosity.

Rules of thumb for gas vs. oil

Use the following rules of thumb for permeability for oil vs. gas reservoirs:

- At >10 millidarcies (md), the reservoir can produce oil without stimulation.

- At >1 md, the reservoir can produce gas without stimulation.

- At 1–10 md, the reservoir probably requires stimulation for oil production.

Effect of authigenic clays

Pore-bridging clays, like illite, decrease porosity slightly but can destroy sandstone permeability. Discrete particle clay, like kaolinite, lowers porosity and permeability only slightly. Figure 2 compares porosity-permeability relationships for kaolinite-, chlorite-, and illite-cemented sandstones. Note there is no significant change in porosities, but permeabilities range over four orders of magnitude.

Figure 3 shows pore lining and discrete particle clays that decrease porosity and permeability only slightly in contrast to pore-bridging clays, which decrease porosity slightly but substantially lower permeability.

Detrital clay and permeability

Detrital clays can be part of sandstone matrix or grains. As matrix, detrital clays can obliterate permeability. Detrital grains of clay are often ductile and can be compacted into pore spaces during burial. The percentage of detrital clay in a rock determines permeability. Figure 4 shows different types of detrital clays in a sandstone.

Effect of quartz overgrowths

In general, as quartz cement precipitates, the pore:pore throat size ratio approaches 1.[5] Throats are reduced less than pore space; therefore, permeability is affected less than porosity. During cementation, the size of the pore spaces between the pore-filling crystals decreases until it approaches the size of the pore throats. Throats become more tabular or sheet-like. Sandstone porosity may be quite low (<5%) and still have some permeability (<10 md) where cemented with quartz. (See also Connectivity and pore throat size.)

Effect of fractures

Fractures enhance the permeability of any sandstone reservoir. Fractures are especially important for improving the permeability of sandstone reservoirs with abundant microporosity or disconnected dissolution porosity.

Predicting from texture and clay content

Predicting sandstone reservoir permeability is possible as long as we realize that potential errors may be large. Any process that decreases pore throat size decreases permeability, so predict accordingly. Use the table below to help predict sandstone reservoir permeability.

| Step | Action |

|---|---|

| 1 | Estimate grain size, sorting, and porosity using the depositional environment. For example, if a reservoir is a beach sand, it should be fine to medium grained and well sorted with well-rounded quartz grains |

| 2 | Apply information from Step 1 to the porosity–permeability–grain size plot (Figure 1). Use porosity and grain size from sandstone to estimate the permeability on the chart. |

| 3 | If the sandstone is poorly sorted or is cemented, then discount permeability downward. |

| 4 | Determine if authigenic clay is present. If so, what kind: pore lining, discrete particle, or pore-throat bridging? Adjust permeability downward according to clay type present. |

| 5 | Determine if detrital clay is present using depositional environment (i.e., high energy = low clay content). If detrital clay is likely, then expect permeability to be low. |

See also

- Sandstone porosity and permeability prediction

- Sandstone diagenetic processes

- Effect of composition and texture on sandstone diagenesis

- Hydrology and sandstone diagenesis

- Influence of depositional environment on sandstone diagenesis

- Predicting sandstone reservoir porosity

- Estimating sandstone permeability from cuttings

- Connectivity and pore throat size

References

- ↑ Coalson, E. B., Hartmann, D. J., and Thomas, J. B., 1990, Applied Petrophysics in Exploration and Exploitation: Notes from short course sponsored by Univ. of Colorado–Denver, var. pages.

- ↑ North, F. K., 1985, Petroleum Geology: London, Allen & Unwin, 607 p.

- ↑ Neasham, J. W., 1977, The morphology of dispersed clay in sandstone reservoirs and its effect on sandstone shaliness, pore space, and fluid flow properties: Proceedings of the SPE Annual Meeting, October 9–12, paper SPE-6858.

- ↑ Wilson, M. D., Pittman, E. D., 1977, Authigenic clays in sandstones: recognition and influence on reservoir properties and paleoenvironmental analysis: Journal of Sedimentary Petrology, vol. 47, no. 1, p. 3–31.

- ↑ Harris, P. M., C. G. St.-C. Kendall, and I. Lerche, 1985, Carbonate cementation—a brief review, in N. Schneidermann and P. M. Harris, eds., Carbonate Cements: SEPM Special Publication 36, p. 79–95.